Condominium

in Ascoli Piceno

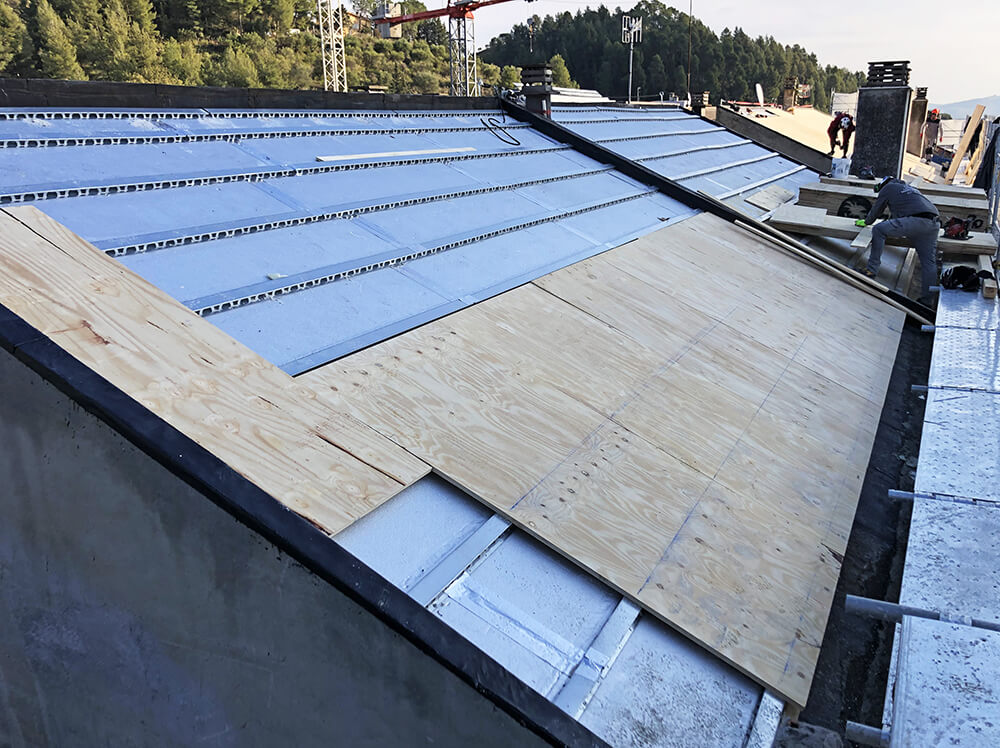

Ventilated roof and facade

| Intervention: | Seismic upgrades and energy-efficiency improvements |

| Location: | Ascoli Piceno (AP) |

| Roof insulation: | Isotec Parete by Brianza Plastica – 100 mm thickness |

| Façade insulation of the top floors: | Isotec Parete Black by Brianza Plastica – 80-120 mm thickness |

| Roof and façade cladding: | Standing-seam metal sheets |

| Energy performance improvement: | From Class F to Class A1 |

The project

The renovation of the large “XXV Aprile” condominium in Ascoli Piceno included seismic upgrades and energy-efficiency improvements, with the aim of enhancing the entire building, which was built in the 1980s, and carrying out an appealing aesthetic restyling that remained true to the original design. The building consists of two main blocks with load-bearing reinforced concrete frames and rises seven storeys above ground, with a basement level used for storage.

The intervention

The Isotec Parete and Isotec Parete Black systems were chosen to provide complete insulation of the upper building envelope. Because the final cladding consisted of standing seam sheet metal, which requires continuous support from OSB panels, Isotec Parete panels were also used as roof insulation. Their flat 8 cm-wide stiffener proved ideal for accommodating the wooden panels, while the wide pitch facilitated faster installation. The 100 mm-thick Isotec Parete panels were fixed to the existing concrete slab with expansion anchors, onto which the OSB panels were then anchored. An anti-condensation membrane was added before laying the double-seam tape cladding, which also serves as the support structure for the photovoltaic system installed on the roof. For the ventilated insulation of the large façade surfaces, the Isotec Parete Black System was chosen for its enhanced fire-resistance performance. Panels were applied with a thickness of 80 mm on the south and north façades, and 120 mm on the shorter west- and east-facing sides.

The result

The energy efficiency and structural consolidation works were completed in less than two years. The rapid progress of the construction site, carried out without requiring condominium residents to vacate their apartments, was further supported by the ease and speed of installing the Isotec Systems, which provide both thermal insulation and an integrated supporting substructure suitable for all types of external cladding.

The outstanding thermal performance of the polyurethane core used in the Isotec System (declared thermal conductivity λD of 0.024-0.025 W/mK depending on thickness for Isotec Parete Black, and 0.022 W/mK for Isotec Parete) resulted in a significant improvement in the condominium’s energy performance, moving from its initial Class F rating (EPgl,nren index of 169.5710 kWh/m² per year) to Class A1 (EPgl,nren index of 41.8228 kWh/m² per year).